ABOUT US

Mindway Technologies Limited has started its journey in the year 2018 with a mission of not only to supplying machinery to the customer but also providing the latest technological solution &necessary consultancy to make it more sustainable and also assure after sales services in 24/7 to our valuable customers.

OUR MISSION

The mission of Mindway Technologies Ltd is to empower the garment industry in Bangladesh with cutting-edge technological solutions that enhance efficiency, sustainability, and product quality, fostering smart growth and global competitiveness with Industry 4.0. The motto of Mindway Technologies Limited's is to provide unique technological solutions distributing a cost-effective wide range of machineries also to provide technical service support by deploying skilled engineers to gain customer satisfactions as a leading technical service-oriented company in all RMG units or apparel industries.

WHAT MAKES US SPECIAL

OUR SERVICES

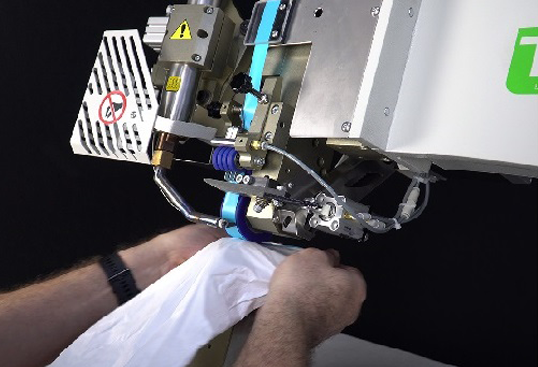

Mindway Technologies Ltd. provides Consultancy for New and Existing Projects (Knit, Woven, Lingerie) in all types of RMG or apparel industries. Mindway Technologies Limited, supplied the world class branded manufacturers machineries from Japan, U.S.A, Italy, Sweden, Spain, Germany, Turkey, China and Korea. Mindway ensures service supports of RMG machineries in 24/7 by skilled and highly experienced engineers.

PRODUCT DEVELOPMENT solution

PRODUCT STORAGE AND PROCESS

AUTOMATIC CUTTING SOLUTIONS

WHY CHOOSE US

Mindway Technologies Ltd. provides Consultancy for New and Existing Projects. Unique and most modern Technical Solutions provider in RMG sector.Mindway ensures service supports of RMG machineries in 24/7 by skilled and highly experienced engineers.

WHAT PEOPLE SAY

Excepteur sint occaecat cupidatat non proident, suntin culpa qui officia deserunt mollit animid est laborum.Phasellus imperdiet lacinia nulla, malesuada semper nibh sodales quis, Duis viverra ipsum dictum.

Excepteur sint occaecat cupidatat non proident, suntin culpa qui officia deserunt mollit animid est laborum.Phasellus imperdiet lacinia nulla, malesuada semper nibh sodales quis, Duis viverra ipsum dictum.

Excepteur sint occaecat cupidatat non proident, suntin culpa qui officia deserunt mollit animid est laborum.Phasellus imperdiet lacinia nulla, malesuada semper nibh sodales quis, Duis viverra ipsum dictum.